BARCODE RIBBONS

DGROUP supplies competitive cost thermal transfer ribbons that suits your barcode printer. Our ribbon ranges from economical to premium grade with great print quality and durability. These ribbons are custom made accordingly your specification. Our comprehensive range of thermal transfer ribbons are compatible to all renowned brands in the market including Toshiba, TSC, Zebra, Sato, Codesoft, Argox, Datamax, GoDEX, Monarch and much more. Below are the types of thermal transfer ribbon available in the market.

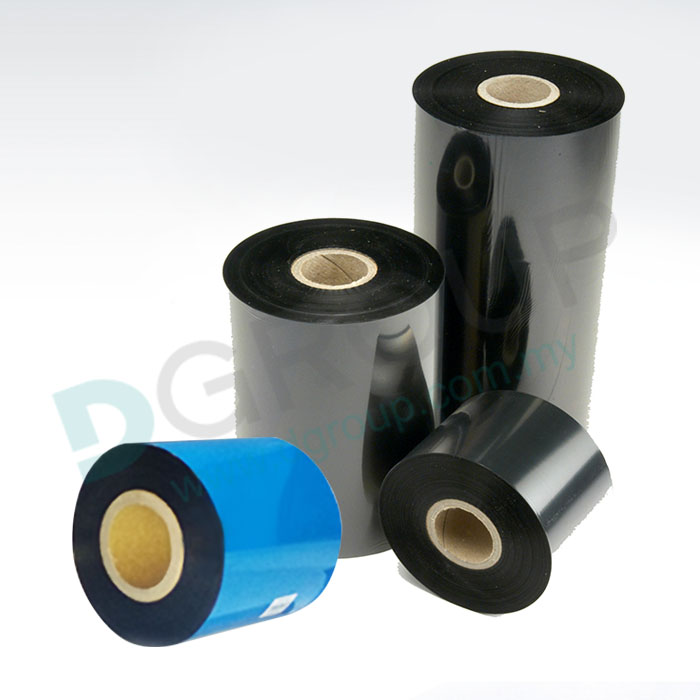

WAX

WAX[Ask for Quote]

Specifications:

- Most cost-effective

- Low melting point due to high wax-based substance.

- Printing can be done at lower heat settings.

- Low scratch, smudge, and chemical resistance.

Common Uses:

- Short-term use.

- Warehousing; inventory tracking.

- Shipping & packaging; shipping information.

- Retail; price and barcode tags.

WAX-RESIN

WAX-RESIN[Ask for Quote]

Specifications:

- Moderately priced

- Resin holds a higher percentage compared to wax. Hence, a mid-heat setting is required.

- Mid scratch, smudge & chemical resistance.

- Withstand moderate temperature change.

Common Uses:

- Lasting print quality for data recording.

- Logistic; parcel and document information.

- Hospital; patient data and documents.

- Warehousing; inventory tracking.

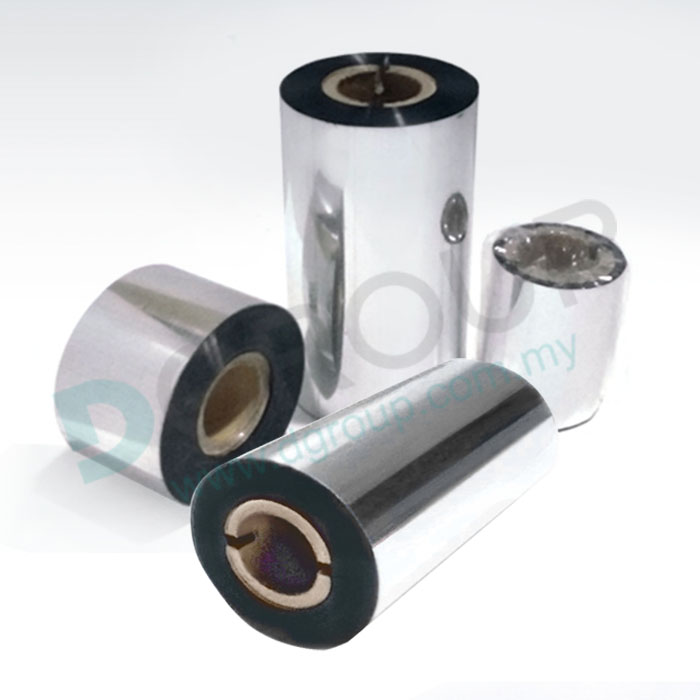

RESIN

RESIN[Ask for Quote]

Specifications:

- Most durable, also most costly.

- Mid to high heat settings required due to high resin-based substance.

- Best choice for harsh & extreme environmental conditions.

- High resistance against scratch, smudge, heat, moisture, UV, and chemicals.

Common Uses:

- For vital info printing.

- Product Labelling; expiry / best before date.

- Barcoding; asset tagging.

- Pharmaceutical; essential data and barcode.

FREQUENTLY ASKED QUESTION - FAQ

1) What is the lifespan of your thermal transfer ribbon when not in use? How do you ensure its longevity?

Thermal transfer ribbon can last up to approximately 24 months (2 years). This is only possible if it is kept indoors at room temperature. Do not expose it to places with high humidity, direct sunlight, or other harsh conditions.

2) Are thermal transfer ribbons only available in black colour?

Black thermal transfer ribbons account for approximately 85–90% of the market due to their high demand and versatility across industries. However, thermal transfer ribbons are also available in a variety of colours, including white, red, blue, and more — ideal for applications requiring colour coding, branding, or enhanced visibility.

3) What is the right ribbon size for my label?

The ribbon is not sized the same as a label. There are three important factors you need to keep in mind:

(i) Width - The ribbon width must be closest to but wider than the label width. For example, if your label width is 38mm, you would want to choose a 40mm ribbon width. With this, you are providing enough space for the ink to fully form your desired image on the label while minimizing the amount of unused ink. Plus, a ribbon width that extends past the edge of the label would also prevent damaging the printerhead made by the label.

(ii) Length - Generally, ribbon length depends on the thermal printer’s capacity. Depending on the model type, the desktop thermal printer able to fit 70 meter, 90 meter, 100 meter or 300 meter ribbon. Industrial printers have larger capacity to fit 300 meter, 450 meter, 600 meter and 900 meter. Larger ribbon capacity means less time is wasted on changing out ribbons between print jobs, maximizing efficiency.

(iii) Core size - The ribbon core size is determined by the printer’s model. The printer can either fits 0.5” core or 1” core. There are newer printer models which can cater to both sizes.

4) Is my thermal transfer ribbon coated side in (FI) or coated out (FO)?

To determine this, simply stick a piece of tape on the outside of your ribbon roll.

Peel it off. If the ink sticks to the tape, your ribbon is coated side out (FO).

If the ink does not stick, the ribbon is coated side in (FI).

5) Must I match my ribbon for my printer based on the brand?

No, thermal transfer ribbons are not brand-specific. Most ribbons, regardless of the brand name, come from the same manufacturing sources and are not made exclusively for specific printer brands. For example, a "Zebra ribbon" is not limited to Zebra printers, and a "TSC ribbon" is not exclusive to TSC models. What truly matters when matching a ribbon to your printer are ribbon type, ink coating side, core size and length. That said, not all ribbons are created equal. The best results come from using high-quality ribbons that are well-matched with your label material and printing application — ensuring optimal print clarity, durability, and performance.

For more information regarding thermal transfer ribbons, read it here.